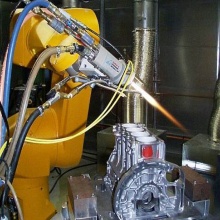

Thermal spray coatings are used for a variety of applications, including wear protection and friction reduction. In the automotive industry, thermal spraying is used as a coating method for the targeted production of cylinder liner surfaces as well as for other engine components in order to meet future performance requirements and emission standards of internal combustion engines.

Due to the possibility of applying various coating materials and their specific surface structure, thermal spray coatings offer significantly improved tribological properties in comparison with other previously used cylinder liner technologies. Furthermore the use of this coating technology on light metal structures can significantly reduce the weight of internal combustion engines and shorten the production process.

Based on the cylinder liner coatings, it can be shown how different novel high-performance coatings influence the tribological properties of internal combustion engines and which improvements in terms of wear and friction reduction can be achieved.