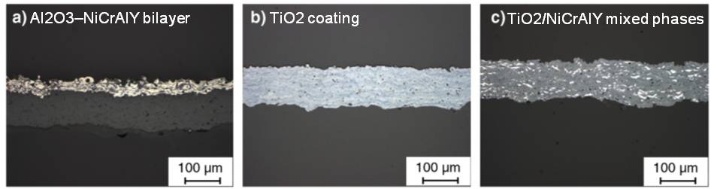

The production of functional coatings on glass or glass ceramic substrates is of outstanding interest in modern product development due to the specific thermophysical properties of glasses, like low or even negative coefficient of thermal expansion, low heat conductivity and high dimensional stability. Ceramic-metal mixed layers as conductive coatings on glass ceramics were thermally sprayed with atmospheric plasma spray. The coatings presents high coating adhesion, coating mechanical stability and thermal resistance up to 200°C, with optimized residual stress distribution and electrical conductivity.

P-525: FLORISTAN, M.; FONTARNAU, R.; KILLINGER, A.; GADOW, R.: Development of electrically conductive plasma sprayed coatings on glass ceramic substrates. In: Surface & Coatings Technology 205 (2010), S. 1021–1028