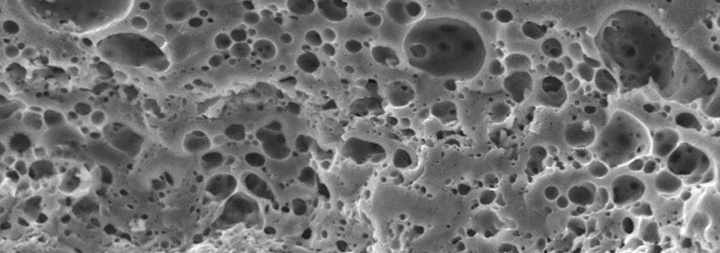

In our modern world, technical surfaces are high demanded. The task of surface technology is to upgrade them and make them functional. It deals with every controlled modification of a component's surface using a variety of technologies for coating, material conversion and material removal processes. The aim is to make surfaces more durable and resistant and to give them tailor-made mechanical, physical and chemical properties.

Research topics

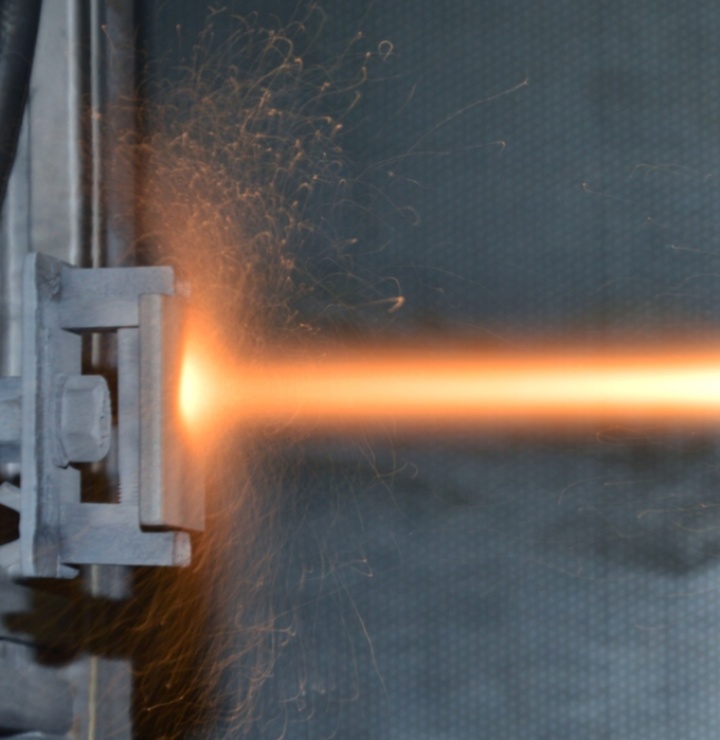

High Velocity Suspension and Solution Flame Spraying (HVSFS, HVSPFS)

Biomedical applications

Manufacturing technologies

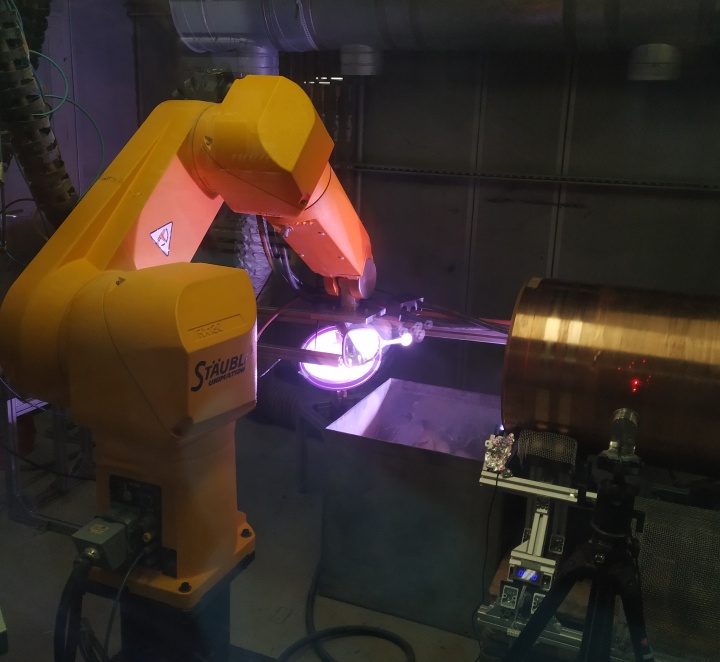

- Three spray cabinets equipped with 6-axis handling robots

- HVOF; HVSFS based on TopGun G, HVOLF based on K2,

- APS, SPS based on F6 single cathode, Magnum three cathode torch

- Wire arc spraying

- Spray lacquer techniques

Materials

- Oxide, carbide and cermet powder materials

- Metals (powder and wire)

- Organic, anorganic and hybrid polymers

Abbreviations

- HVOF = High Velocity Oxy Fuel Spraying

- HVSFS = High Velocity Suspension Flame Spraying

- APS = Atmospheric Plasma Spraying

- SPS = Suspension Plasma Spraying

- HVOLF = High Velocity Oxy Liquid Fuel Spraying

Your contact person

Andreas Killinger

apl. Prof. Dr. rer. nat.Assistant Director of the Institute

Head of surface technologies and composites group