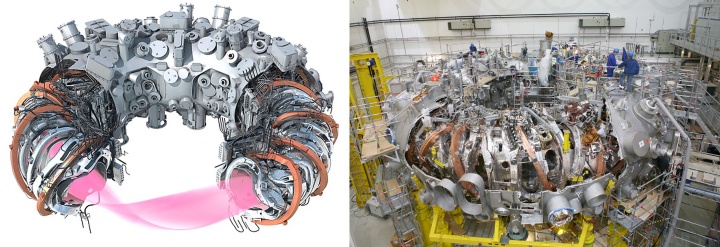

Fusion energy is perhaps the solution of our worldwide energy problem. It may offer unlimited and CO2 neutral energy for many hundred years. But the technology behind is still one of the greatest technical challenges of human mankind. Since decades, an ongoing intense international research is bringing us step by step closer to the goal to use nuclear fusion as an energy source. The world's largest torus shaped stellarator type nuclear fusion reactor at present is operated at the Max Planck Institute for Plasma Physics in Greifswald, the so called Wendelstein 7-X (Fig. 1). It is still a research facility to study the possibilities to trap, heat and control the ultra-hot plasma that is necessary to start-up and keep the fusion reaction running.

Electron cyclotron radio frequency heating systems (140 GHz, microwave radiation) are required to heat up and maintain the plasma that is entrapped within the torus. To remove gaseous reaction products out of the plasma during operation, cryopumps are integrated and operated within the torus. They are running under high microwave strayfield radiation and therefor need radiation protection shields. Copper based and water-cooled baffle shield are acting as “first wall shields” thus protecting the liquid Nitrogen and Helium cryopanes from microwave radiation and preventing an undesired heating of these components.

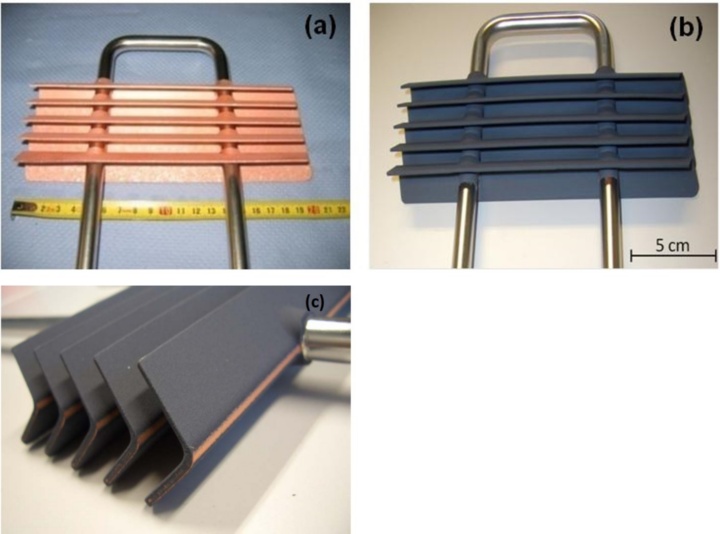

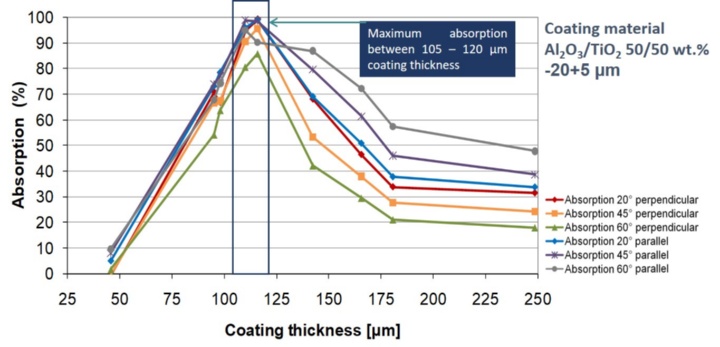

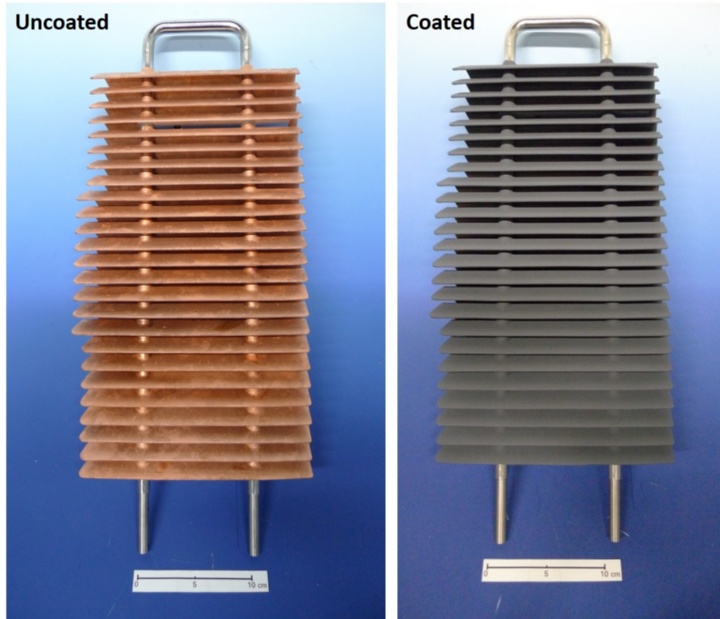

The water baffles therefor should efficiently absorb microwave radiation. To improve absorption ability on the copper surface of the water-cooled lamella, oxide ceramic absorber layer systems have been developed and tested at the IFKB in collaboration with the IPP in Greifswald and the IPF (now IGVP) at the University of Stuttgart. Material composition and thickness was tailored to achieve a maximum absorption for 140 GHz radiation. The coatings show a high thermal resistivity and are suitable to be operated under ulltrahigh vacuum conditions.

Absorption values up to 90% (depending on the radiation impact angle) could be achieved. To coat the entire area of the copper lamella that form the heat exchanger, the so-called chevrons, by means of atmospheric plasma spraying (APS), the spray process had to be adapted to the unusual component geometry through the development of a sophisticated robot-guided spray torch kinematic.

P-570: FLORISTÁN, M.; GADOW, R.; GEBHARDT, A.; MÜLLER, P.; KILLINGER, A.; CARDELLA, A.; LI, C.; STADLER, R.; ZANGL, G.; HIRSCH, M.; LAQUA, H. P.; KASPAREK, W.: Development and testing of a 140 GHz absorber coating for the water baffle of W7-X cryopumps. In: Fusion Engineering and Design 86 (2011), S. 1847–1850, doi:10.1016/j.fusengdes.2010.12.015

Your contact person

Andreas Killinger

apl. Prof. Dr. rer. nat.Assistant Director of the Institute

Head of surface technologies and composites group