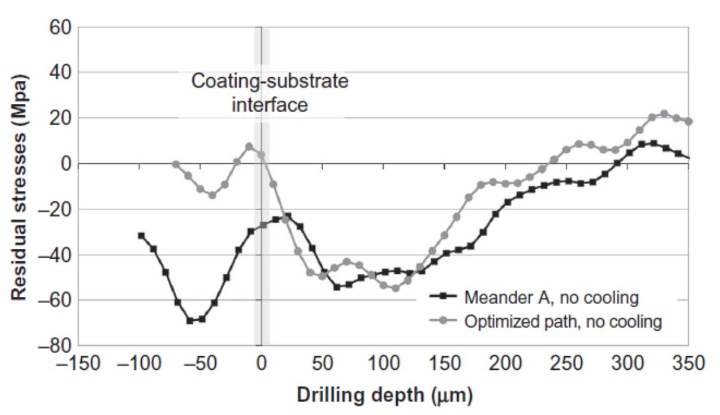

Residual stresses are related to the thermophysical properties of substrate and coating materials and occur after the coated component has undergone thermal spraying and machining processes. All residual stresses in layer composites result from different individual stress mechanisms occurring during the manufacturing process, mainly based on heat and mass transfer during the coating deposition. Using the hole-milling-and-drilling method, residual stress fields can be measured in a quasi-nondestructive way over the drilling depth with high resolution.

P-253: BUCHMANN, M.; ESCRIBANO, M.; GADOW, R.: Residual Stress Analysis in thermally sprayed layer composites, using the Microhole Milling and Drilling Method. In: Journal of Thermal Spray Technology 14 (2005), Nr. 1, S. 100–108, ISSN 1059-9630

P-353: WENZELBURGER, M.; LOPÉZ, D.; GADOW, R.: Methods and application of residual stress analysis in thermally sprayed coatings and composites. In: Surface and Coatings Technology 201 (2006). Nr. 5, S. 1995–2001, ISSN: 0257-8972