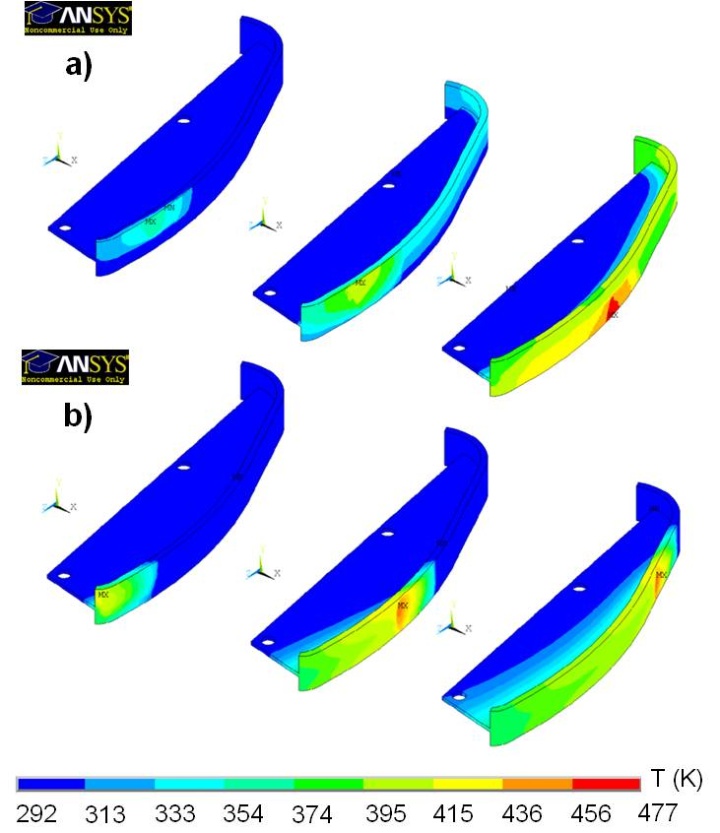

During thermal spraying, a variety of process parameters takes influence on the final composite properties (coating adhesion, residual stresses, porosity, etc.) and on the reliability of the mechanical component. Modeling and simulation can be used for a differentiated analysis of influences and interrelations of key parameters on the process. Simulation of heat and mass transfer is an essential tool for the evaluation of residual stress formation and for a better planning of process design and torch kinematics.

P-366: CANDEL, A.; GADOW, R.; WENZELBURGER, M.: Modeling and simulation of heat and mass transfer and of process automatization for the coating of complex geometries by thermal spraying. In: 8th CIRP International Workshop on Modeling of Machining Operations, Proceedings, ed. R. Neugebauer, Verlag Wissenschaftliche Scripten, Zwickau (2005), S. 147–156

P-289: ESCRIBANO, M.; GADOW, R.; WENZELBURGER, M.: Modeling of thermally sprayed coatings on light metal substrates – Layer growth and residual stress formation. In: Surface & Coatings Technology 180 (2004), S. 429–435, ISSN: 0257-8972/04