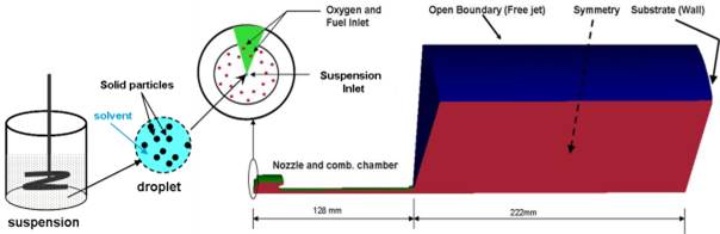

The interest in submicron and nano-structured layers applied by thermal spray coating technologies on mechanical components has been significantly increased during the last decade. High Velocity Suspension Flame Spraying (HVSFS) has been developed for the processing of nano-structured spray material to achieve dense surface layers in supersonic mode with a refined structure, from which superior mechanical and physical properties are expected. However, the chemical and thermo-dynamic phenomena occurring in HVSFS reacting flow field are a challenging, multidisciplinary issue.

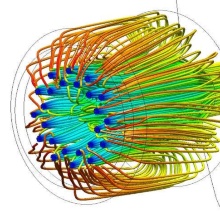

Studies intended to analyze and understand the HVSFS combustion and flow dynamic system on the basis of a CFD model are performed. The model considers following phenomena: combustion of the fuel gas (premixed), energies transfer between the flame and the suspension droplets (organic solvent and particles), and the injection, vaporization and combustion of the suspension organic solvent (non-premixed).

P-497: DONGMO. E. ; GADOW, R. ; KILLINGER, A. ; WENZELBURGER, M.: Modeling of Combustion as well as Heat, Mass, and Momentum Transfer During Thermal Spraying by HVOF and HVSFS. In: Journal of Thermal Spray Technology 18 (2009), Nr. 5–6, S. 896–908

P-474: DONGMO, E.; GADOW, R.; KILLINGER, A.; WENZELBURGER, M.: Numerical Approach and Optimization of the Combustion and Gas Dynamics in High Velocity Suspension Flame Spraying (HVSFS). In: Surface & Coatings Technology 203 (2009), Nr. 15, S. 2139–2145

P-436: DONGMO, E.; GADOW, R.; WENZELBURGER, M.: Analysis and Optimization of the HVOF Process by Combined Experimental and Numerical Approaches. In: Surface & Coatings Technology 202 (2008), Nr. 18, S. 4470–4478